Using Mixed Reality Technologies to Improve Solution Acquisition Processes for Your MedTech Facility

There is a constant need to advance in all industries, using new technologies, work practices, and methodologies to drive efficiencies and enhance productivity. At Pharmaceutical Stainless Supplies, one area where we have made considerable advances in recent months is the use of mixed reality technologies.

Using mixed reality, we are able to cut the time it takes to develop new products and solutions for our MedTech industry customers. In addition, we can identify problems and challenges at the earliest stages of the design process, saving even more time.

Our use of mixed reality technology also allows us to cut costs in various areas. Examples include:

- Achieving improved efficiencies

- The better management of risk in the design process

- Largely eliminating the need for physical travel until it is necessary to ship the final product and install it at your location

Understanding the Different Technologies

Mixed reality technology is the lesser-known of the three technologies that fall into this broad spectrum. The two more well-known options are virtual reality and augmented reality.

At the virtual reality end of the spectrum, you block out the physical world and replace it with a digital experience.

You can think of augmented reality as being at the other end of this spectrum. It is where you keep the physical world while overlaying it with digital elements.

Mixed reality occupies the much larger area in the centre of this spectrum.

Mixed reality is far too big a topic to cover here, plus it has a multitude of real and potential use cases in a wide range of industries.

At Pharmaceutical Stainless Supplies, we apply the technology to very specific processes.

Applying Mixed Reality to the Design Process

Our business involves designing and manufacturing high-specification and fully customised stainless-steel products for clients in the MedTech, pharmaceutical, and biotech industries. Those products include cleanroom furniture, material handling solutions, process pipework, and more.

As a result, there is a design aspect to almost every project we work on. We rarely, however, design products in isolation. Instead, the products we design must interact or fit in with other spaces, equipment, processes, and more.

Take cleanroom furniture as an example. Specifically, the design and manufacture of a washing station in a cleanroom. That washing station is likely to be located in the cleanroom based on:

- The space available

- The architectural features of the room (location of doors, services, equipment, pre-existing furniture, etc)

- The facility’s gowning procedures

To design this washing station, we would normally receive measurements and specifications from our client. However, we can’t be sure that something in the room hasn’t been missed. After all, this is easy to do, particularly given the challenges of imagining a piece of furniture in a room when all you are looking at is a blank space.

A site visit solves these problems, but this increases the time it takes to complete the design as well as increasing costs.

The Mixed Reality Solution

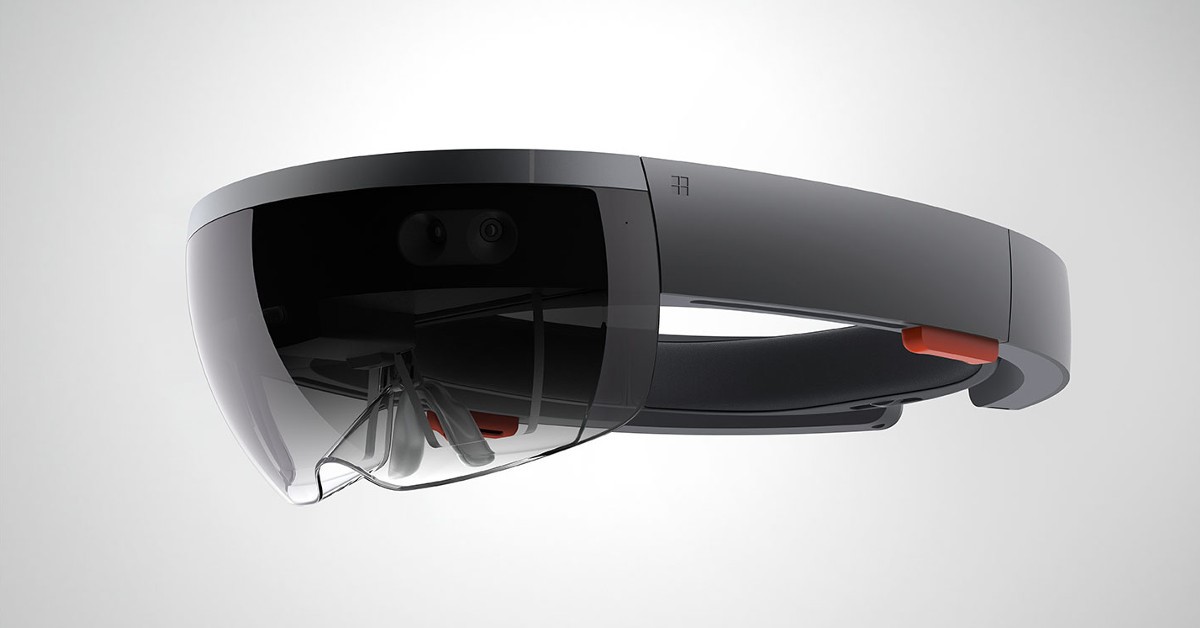

Mixed reality technologies are the solution. We use Microsoft HoloLens at Pharmaceutical Stainless Supplies, a platform that lets us create a 3D model of the product we are designing.

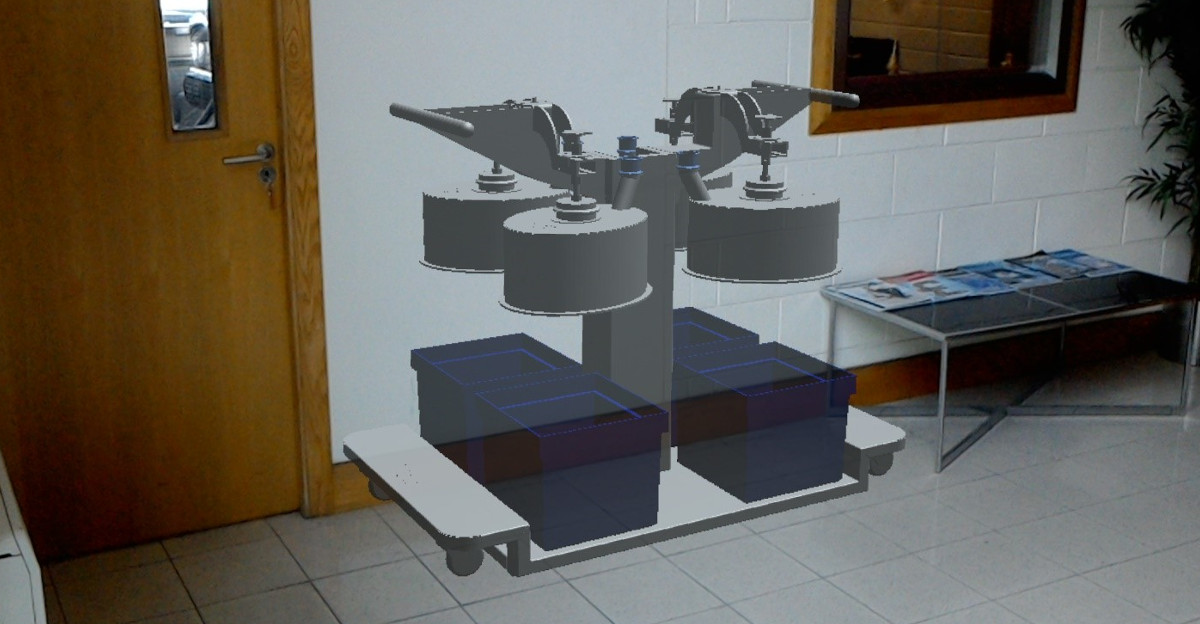

Using Microsoft HoloLens at their facility, our client can then see the 3D model virtually represented in their cleanroom. Crucially – and this is one of the main differences between mixed reality and augmented reality technologies – our 3D model is anchored to its location in the cleanroom just like it would be in real life.

If pipework from another piece of equipment or something jutting out from the wall prevents the 3D model from anchoring to its position properly, we will know.

Plus, our client knows too as they are looking at the same thing we are, even though they are in their location (wherever they are in the world) and we are in our location (in Sligo, Ireland) looking at their cleanroom as if we were standing beside them.

During this whole process, we will be communicating with the client via a video conference call, all within the mixed reality experience.

Extensive Potential

The above is just one example of our use of mixed reality technologies at Pharmaceutical Stainless Supplies. That said, it’s a fantastic example of this emerging and highly effective tool.